Pipe Fitting: A Look into the Trade, Skills, and Career Path

Pipe fitting is a highly skilled trade that plays a critical role in modern construction, manufacturing, and infrastructure. While many people picture plumbing as sinks and toilets, pipe fitting operates on a much larger and more technical scale. It focuses on assembling, installing, and maintaining piping systems that move fluids and gases through commercial, industrial, and institutional environments.

From power plants and hospitals to office towers and factories, pipe fitters are responsible for systems that must operate safely under pressure, temperature extremes, and continuous use. This article takes a focused look at what pipe fitting involves, the skills required, the environments pipe fitters work in, and what the career path typically looks like in the United States.

What Pipe Fitting Work Involves

At its core, pipe fitting is about precision. Pipe fitters install piping systems that carry substances such as water, steam, air, chemicals, fuel, and refrigerants. These systems are often part of larger mechanical networks, including HVAC systems, industrial processing lines, and energy infrastructure.

Unlike smaller-scale piping found in homes, pipe fitting projects usually involve:

- Larger pipe diameters

- Higher operating pressures

- More complex layouts

- Specialized materials

- Tighter tolerances

Pipe fitters work from detailed blueprints and technical drawings, carefully measuring, cutting, aligning, and joining pipe sections so systems function exactly as designed. Small errors can lead to leaks, vibration, or long-term system failure, which is why accuracy matters so much in this trade.

Common Environments Where Pipe Fitters Work

Pipe fitting is most often associated with large or technically demanding settings.

Commercial buildings

Office towers, shopping centers, hotels, and hospitals rely on extensive piping systems hidden behind walls and ceilings. Pipe fitters install chilled water loops, heating systems, mechanical room piping, and utility connections that serve entire buildings.

Industrial facilities

Factories, refineries, food processing plants, and chemical facilities require piping systems designed to handle heat, pressure, corrosion, and continuous operation. These environments demand advanced skills and strict adherence to safety standards.

Energy and power infrastructure

Power plants, renewable energy facilities, and utility systems depend on pipe fitters to install steam lines, fuel systems, and cooling circuits that keep energy production running reliably.

Institutional settings

Schools, universities, laboratories, and government buildings often include complex mechanical systems where pipe fitting expertise is essential.

Materials Used in Pipe Fitting

Pipe fitters work with a wide range of materials, chosen based on pressure requirements, temperature ranges, corrosion resistance, and the type of substance being transported.

Common materials include:

- Carbon steel

- Stainless steel

- Alloy steel

- Copper

- Cast iron

- PVC, CPVC, and specialty plastics

Each material behaves differently when cut, heated, welded, or pressurized. Understanding these characteristics is a core part of pipe fitting skill and experience.

Pipe Joining Methods and Techniques

Joining pipe sections is one of the most technical aspects of pipe fitting. The method used depends on system requirements, material type, and code standards.

Common joining methods include:

- Welding

- Brazing

- Soldering

- Threading

- Grooved couplings

- Flanged connections

In many industrial applications, welding is the dominant method. Pipe fitters must produce welds that are structurally sound, leak-free, and capable of withstanding extreme conditions over long periods of time. Poor workmanship can result in system shutdowns, safety hazards, and costly repairs.

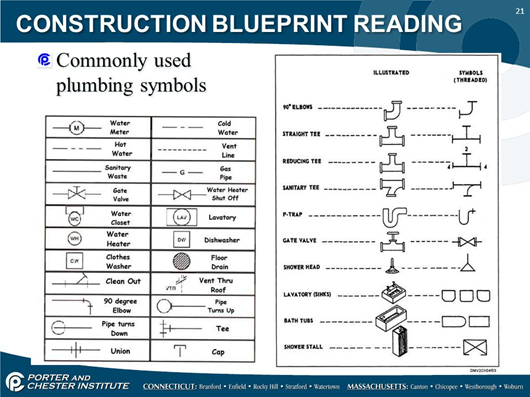

Reading Blueprints and System Layouts

Pipe fitters rely heavily on technical drawings. These blueprints show pipe routes, elevations, connection points, valve locations, and equipment interfaces. Being able to read isometric drawings and mechanical plans is essential to the job.

On complex projects, pipe fitters may also:

- Coordinate with engineers and project managers

- Adjust layouts to accommodate real-world site conditions

- Ensure proper slope, expansion allowance, and pipe support placement

- Verify alignment with structural and mechanical systems

This planning and coordination aspect is one reason pipe fitting is considered a high-skill trade rather than simple installation work.

Safety and Precision on the Job

Safety is a major focus in pipe fitting. Many systems involve hazardous materials, high pressure, or extreme heat. A single mistake can cause serious injuries, environmental damage, or major equipment failure.

Pipe fitters routinely follow strict safety procedures, including:

- Lockout and tagout protocols

- Confined space rules

- Proper use of personal protective equipment

- Fire prevention measures during welding or cutting

- Pressure testing before systems are placed into service

Precision is just as important as safety. Pipes must align correctly to avoid stress, vibration, and premature wear once systems are operating.

Training and Skill Development

Pipe fitting requires extensive training. Most professionals enter the trade through apprenticeships that combine classroom instruction with hands-on field experience.

Training typically includes:

- Blueprint reading

- Applied mathematics and measurements

- Welding and fabrication techniques

- Pipe layout and installation

- Safety regulations and best practices

- Mechanical system fundamentals

Apprenticeships often last several years, reflecting the technical nature of the work. Even experienced pipe fitters continue learning throughout their careers as materials, codes, and system designs evolve.

Career Opportunities and Salary Range

Pipe fitting offers strong career opportunities across multiple industries, especially as infrastructure ages and new facilities are built.

Common career paths include:

- Commercial construction projects

- Industrial maintenance and shutdown work

- Energy and utility sector roles

- Specialized welding positions

- Foreman or supervisory roles

- Inspection and quality control positions

In terms of pay, pipe fitting is generally well-compensated compared to many other construction trades. In the U.S., entry-level apprentices typically earn while they learn, often starting in the lower range of the trade pay scale. Experienced pipe fitters commonly earn solid middle-to-upper five-figure annual incomes, with higher earnings possible in industrial, energy, or unionized roles. Overtime, night shifts, and specialized welding certifications can significantly increase total compensation.

Job stability is another advantage. Skilled pipe fitters are consistently in demand due to ongoing maintenance needs, industrial expansion, and large-scale construction projects.

Pipe Fitting and Modern Building Systems

Modern buildings rely heavily on efficient mechanical systems. Energy-efficient heating and cooling, sustainable water use, and advanced manufacturing processes all depend on properly designed and installed piping networks.

Pipe fitters contribute directly to:

- Energy efficiency improvements

- Reduced system downtime

- Environmental protection

- Long-term building and equipment performance

As building technology becomes more advanced, the role of pipe fitters continues to grow in both scope and importance.

The Importance of Pipe Fitters in Infrastructure

Much of the infrastructure people depend on every day operates out of sight. Steam lines heating buildings, chilled water systems cooling offices, and industrial pipelines supporting manufacturing all exist because skilled pipe fitters installed them correctly.

Pipe fitting is not just about connecting pipes. It is about building the systems that keep modern cities, industries, and facilities operating safely and efficiently.